Swarovski Crystal prodotti in Ungheria

il miglior prezzo di vendita al dettaglio, il più grande assortimento.

Prodotti disponibili per l'acquisto presso i negozi

immediatamente personale, o può essere ordinato on-line!

il miglior prezzo di vendita al dettaglio, il più grande assortimento.

Prodotti disponibili per l'acquisto presso i negozi

immediatamente personale, o può essere ordinato on-line!

Swarovski Elements Categorie

(2434 prodotti)

- Prossimamente

- Nuovi prodotti

- Prodotti Swarovski fabbricati singolarmente (3 prodotti)

-

Swarovski Round Stones (9 prodotti)

- Swarovski 1028 XILION Chaton (64 colori)

- Swarovski 1088 XIRIUS Chaton (26 colori)

- Swarovski 1100

- Swarovski 1122 Rivoli Chaton (58 colori)

- Swarovski 1128 (1 colori)

- Swarovski 1318 Flower Cut (1 colori)

- Swarovski 1357 Brilliant Cut (10 colori)

- Swarovski 1480 Cabochon Chaton (5 colori)

- Swarovski 1681 Vision Round Stone (5 colori)

-

Swarovski Flat Backs No Hotfix (28 prodotti)

- Swarovski 2000 Rose (9 colori)

- Swarovski 2006 Rivoli Flat Back

- Swarovski 2028,2058,2088 (109 colori)

- Swarovski 2035 Chessboard Circle (2 colori)

- Swarovski 2037 Eclipse (7 colori)

- Swarovski 2204 Pure Leaf (2 colori)

- Swarovski 2304 Rain Drop (1 colori)

- Swarovski 2400 Square

- Swarovski 2483 Classic Square (1 colori)

- Swarovski 2493 Chessboard (4 colori)

- Swarovski 2520 Cosmic (6 colori)

- Swarovski 2555 Cosmic Baguette (5 colori)

- Swarovski 2585 Graphic (3 colori)

- Swarovski 2611 Solaris (1 colori)

- Swarovski 2708 Molecule (8 colori)

- Swarovski 2709 Rhombus (4 colori)

- Swarovski 2716 Rivoli Triangle (4 colori)

- Swarovski 2720 Cosmic Delta (9 colori)

- Swarovski 2721 Asymmetric Triangle (1 colori)

- Swarovski 2770 Wing (6 colori)

- Swarovski 2797 Diamond Leaf (4 colori)

- Swarovski 2808 (4 colori)

- Swarovski 2816 Rivoli Star (3 colori)

- Swarovski 2826 Rivoli Snowflake (3 colori)

- Swarovski 2854 Butterfly (5 colori)

- Swarovski 4841 (3 colori)

- Swarovski 4854 (2 colori)

- Swarovski 4869 (9 colori)

-

Swarovski Flat Backs Hotfix (9 prodotti)

- Swarovski 2028,2038,2078 (90 colori)

- Swarovski 2080/4 Cabochon Round (6 colori)

- Swarovski 2200 Navette (2 colori)

- Swarovski 2300 Drop (1 colori)

- Swarovski 2400 Square (6 colori)

- Swarovski 2711 Triangle (1 colori)

- Swarovski 2720 Cosmic Delta (2 colori)

- Swarovski 2808 szív (1 colori)

- Swarovski 2028 Hotfix (13 colori)

- Swarovski Kristály Pixie

-

Swarovski Fancy Stones & Settings

-

Swarovski Fancy Settings (31 prodotti)

- Swarovski 4120/S (1 colori)

- Swarovski 4127/S (1 colori)

- Swarovski 4128/S (1 colori)

- Swarovski 4200/S (2 colori)

- Swarovski 4224/S (1 colori)

- Swarovski 4228/S (3 colori)

- Swarovski 4230/S (1 colori)

- Swarovski 4320/S (1 colori)

- Swarovski 4327/S (1 colori)

- Swarovski 4328/S (2 colori)

- Swarovski 4428/S (1 colori)

- Swarovski 4461/S (2 colori)

- Swarovski 4470/S (2 colori)

- Swarovski 4500/S (1 colori)

- Swarovski 4501/S (1 colori)

- Swarovski 4505/S (1 colori)

- Swarovski 4527/S (1 colori)

- Swarovski 4565/S (1 colori)

- Swarovski 4600/S (1 colori)

- Swarovski 4610/S (1 colori)

- Swarovski 4675/S (1 colori)

- Swarovski 4681/S (1 colori)

- Swarovski 4722/S (1 colori)

- Swarovski 4739/S (1 colori)

- Swarovski 4744/S (1 colori)

- Swarovski 4779/S (1 colori)

- Swarovski 4778/S (1 colori)

- Swarovski 4789/S (1 colori)

- Swarovski 4827/S (1 colori)

- Swarovski 4831/S (1 colori)

- Swarovski 4884/S (1 colori)

-

Swarovski Fancy Stones (35 prodotti)

- Swarovski 4120 (14 colori)

- Swarovski 4127 (1 colori)

- Swarovski 4128 XILION Oval (18 colori)

- Swarovski 4161 Long Classical Oval (1 colori)

- Swarovski 4196 (1 colori)

- Swarovski 4200 (7 colori)

- Swarovski 4224 (2 colori)

- Swarovski 4228 XILION Navette (31 colori)

- Swarovski 4230 Lemon Fancy Stone (1 colori)

- Swarovski 4320 (11 colori)

- Swarovski 4327 (6 colori)

- Swarovski 4328 XILION Pear (13 colori)

- Swarovski 4428 XILION Square (7 colori)

- Swarovski 4447 Princess Square (6 colori)

- Swarovski 4470 (8 colori)

- Swarovski 4481 Vision Square Fancy Stone (5 colori)

- Swarovski 4501 (1 colori)

- Swarovski 4505 (1 colori)

- Swarovski 4527 (6 colori)

- Swarovski 4547 Princess Baguette (1 colori)

- Swarovski 4565 Classical Baguette (6 colori)

- Swarovski 4600 (1 colori)

- Swarovski 4610 (6 colori)

- Swarovski 4681 Vision Hexagon FS (5 colori)

- Swarovski 4717 (2 colori)

- Swarovski 4722 (1 colori)

- Swarovski 4739 Cosmic Fancy Stone (1 colori)

- Swarovski 4744 Flower (7 colori)

- Swarovski 4745 Star (6 colori)

- Swarovski 4778 Fatima Hand Fancy Stone (1 colori)

- Swarovski 4778 Buddha Fancy Stone (1 colori)

- Swarovski 4789 (5 colori)

- Swarovski 4831 (1 colori)

- Swarovski 4884 (11 colori)

- Swarovski 4500 (1 colori)

-

Swarovski Fancy Settings (31 prodotti)

-

Swarovski Sew-on Stones (17 prodotti)

- Swarovski 3128 XILION Lochrose (4 colori)

- Swarovski 3204 XILION (4 colori)

- Swarovski 3210 Oval (10 colori)

- Swarovski 3223 Navette (2 colori)

- Swarovski 3230 Drop (13 colori)

- Swarovski 3231 Owlet (5 colori)

- Swarovski 3240 Square (2 colori)

- Swarovski 3250 Rectangle (4 colori)

- Swarovski 3254 Diamond Leaf (6 colori)

- Swarovski 3255 Cosmic Baguette

- Swarovski 3256 Galactic (5 colori)

- Swarovski 3259 Heart Sew-on (2 colori)

- Swarovski 3261 Hexagon (7 colori)

- Swarovski 3265 Cosmic (7 colori)

- Swarovski 3270 Triangle (1 colori)

- Swarovski 3400 Square (4 colori)

- Swarovski 3700 Marguerite (11 colori)

-

Swarovski Beads (46 prodotti)

- Swarovski 5000 (67 colori)

- Swarovski 5003

- Swarovski 5005 Chessboard

- Swarovski 5020 Helix (2 colori)

- Swarovski 5040 Briolette (8 colori)

- Swarovski 5041 Briolette (2 colori)

- Swarovski 5100

- Swarovski 5139 Ring (3 colori)

- Swarovski 5150 Modular Bead (1 colori)

- Swarovski 5180 Square (4 colori)

- Swarovski 5181 Keystone (3 colori)

- Swarovski 5200

- Swarovski 5203 Polygon (1 colori)

- Swarovski 5205

- Swarovski 5305 (2 colori)

- Swarovski 5308

- Swarovski 5328 XILION Bead (100 colori)

- Swarovski 5500 (1 colori)

- Swarovski 5520 Graphic Bead (4 colori)

- Swarovski 5523 Cosmic Bead

- Swarovski 5525 Wave Bead (2 colori)

- Swarovski 5534 Column

- Swarovski 5535 Column (8 colori)

- Swarovski 5541 Dome Bead large (2 colori)

- Swarovski 5542 Dome Bead small (4 colori)

- Swarovski 5590 Wing Bead

- Swarovski 5603 Graphic Cube (1 colori)

- Swarovski 5621 Twist Bead

- Swarovski 5624 (4 colori)

- Swarovski 5650 Cubist Bead (7 colori)

- Swarovski 5714 Star (2 colori)

- Swarovski 5727 Fish (3 colori)

- Swarovski 5728

- Swarovski 5743 Heart (2 colori)

- Swarovski 5744 Flower (2 colori)

- Swarovski 5748 Arrow Bead

- Swarovski 5750 Skull Bead (1 colori)

- Swarovski 5752 (2 colori)

- Swarovski 5754 Butterfly

- Swarovski 5900

- Swarovski 5914 Star (1 colori)

- Swarovski 5940 (9 colori)

- Swarovski 5942 Heart

- Swarovski 5944 Flower Bead (3 colori)

- Swarovski 5954 Butterfly

- Swarovski 86001 (9 colori)

-

Swarovski Crystal Pearls (9 prodotti)

- Swarovski 5810 Crystal Round (31 colori)

- Swarovski 5811 Crystal Round (13 colori)

- Swarovski 5816 (11 colori)

- Swarovski 5817 (14 colori)

- Swarovski 5818 (5 colori)

- Swarovski 5821 Crystal Pear-shaped (10 colori)

- Swarovski 5826 Crystal Curved (5 colori)

- Swarovski 5840 Crystal Baroque (8 colori)

- Swarovski 5860 (15 colori)

-

Swarovski Pendants (56 prodotti)

- Swarovski 4139 Cosmic Ring (1 colori)

- Swarovski 4437 Cosmic Square (4 colori)

- Swarovski 4439 Square Ring (4 colori)

- Swarovski 4736 Cosmic Triangle (1 colori)

- Swarovski 4737 (7 colori)

- Swarovski 6000 (6 colori)

- Swarovski 6007 Small Briolette (7 colori)

- Swarovski 6902 Zinnia Pendant (1 colori)

- Swarovski 6010 Briolette Pendant (3 colori)

- Swarovski 6012 Flat Briolette (3 colori)

- Swarovski 6015 Polygon Drop (2 colori)

- Swarovski 6019/G Crystalactite Pend. petite (1 colori)

- Swarovski 6020 Helix Pendant (1 colori)

- Swarovski 6026 Cabochette Pendant (1 colori)

- Swarovski 6040 Helios Pendant (4 colori)

- Swarovski 6058 Metro Pendant (1 colori)

- Swarovski 6090 Baroque Pendant (6 colori)

- Swarovski 6091 Baroque Pendant (1 colori)

- Swarovski 6100 (1 colori)

- Swarovski 6106 Pear Pendant (3 colori)

- Swarovski 6128 Mini Pear Pendant (1 colori)

- Swarovski 6190 Rock Pendant (10 colori)

- Swarovski 6191 Divine Rock Pendant (4 colori)

- Swarovski 6202 Heart Pendant (5 colori)

- Swarovski 6210 Round Pendant

- Swarovski 6215 Heart Pendant (2 colori)

- Swarovski 6225 Heart Pendant (2 colori)

- Swarovski 6228 Heart Pendant (30 colori)

- Swarovski 6240 Wild Heart Pendant (6 colori)

- Swarovski 6261 Devoted 2 U Heart Pendant (6 colori)

- Swarovski 6263 Forever 1 Heart Pendant (3 colori)

- Swarovski 6301,6328 XILION Bicone Pendant (4 colori)

- Swarovski 6401 Octagon Pendant (2 colori)

- Swarovski 6428 XILION Pendant (3 colori)

- Swarovski 6470 Ellipse Pendant (2 colori)

- Swarovski 6480 Spike Pendant (3 colori)

- Swarovski 6525 Wave Pendant (4 colori)

- Swarovski 6532 Pure Drop Pend. tr.cap (2 colori)

- Swarovski 6541 Twisted Drop Pend. cl.cap (2 colori)

- Swarovski 6620 Avant-Garde Pendant (5 colori)

- Swarovski 6656 Galactic Vertical (1 colori)

- Swarovski 6670 De-Art Pendant (9 colori)

- Swarovski 6680 Cosmic Pendant (1 colori)

- Swarovski 6685 Graphic Pendant (2 colori)

- Swarovski 6690 Wing Pendant (13 colori)

- Swarovski 6723 Shell Pendant (2 colori)

- Swarovski 6724 Sun Pendant (1 colori)

- Swarovski 6730

- Swarovski 6731

- Swarovski 6744 Flower Pendant (5 colori)

- Swarovski 6754 Butterfly Pendant (3 colori)

- Swarovski 6866 Cross Pendant (1 colori)

- Swarovski 6867 (6 colori)

- Swarovski 6871 (1 colori)

- Swarovski 6904 Lily Pendant (2 colori)

- Swarovski 6919 The key to happiness (1 colori)

- Swarovski Plastic Trimmings

- Swarovski Buttons

- Swarovski Metal Trimmings

- Swarovski Crystal Mesh

- Swarovski Cupchains & Findings

-

Swarovski Knobs, Handles & Co (15 prodotti)

- Swarovski 7100 Ball (1 colori)

- Swarovski 7110 3/4 Ball

- Swarovski 7125 Half Ball Contemporary Cut (1 colori)

- Swarovski 7130 Half Ball With Hole (1 colori)

- Swarovski 7150 Chaton Handle

- Swarovski 7155 Globe Handle (1 colori)

- Swarovski 7156 Globe Handle (1 colori)

- Swarovski 7157 Globe Handle

- Swarovski 7160 Tube Handle (2 colori)

- Swarovski 7165 Inlay (3 colori)

- Swarovski 7170 Insert (1 colori)

- Swarovski 7300 Pin (1 colori)

- Swarovski 7305 Round Lever Handle

- Swarovski 7306 Sphere Handle (1 colori)

- Swarovski 7315 Centerpart Blind Hole (1 colori)

- Swarovski Lighting Collection (2 prodotti)

- Accessori (2 prodotti)

Tasso di euro correnti

380 Ft

380 Ft

I prezzi in euro sono

prezzi solo informativi!

prezzi solo informativi!

Impostazione della data

2025.12.03 18:04

2025.12.03 18:04

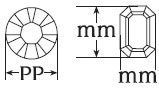

Size Conversion Reference

Sizes

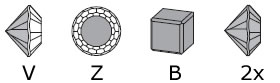

Foiling

Surface Effects

Translucent Effects

Variations on Surface Effects

Special Surface Effects

Hotfix Technology